LASER CUT RAILING MANUFACTURER

- HOME

- LASER CUT RAILING

LASER CUT RAILING

Laser cut railing refers to a type of railing design or construction process that involves the use of laser cutting technology. In this method, a laser cutting machine is employed to precisely cut through various materials, creating intricate and detailed patterns or designs on the railing components.

OUR LASER CUT RAILING SYSTEMS

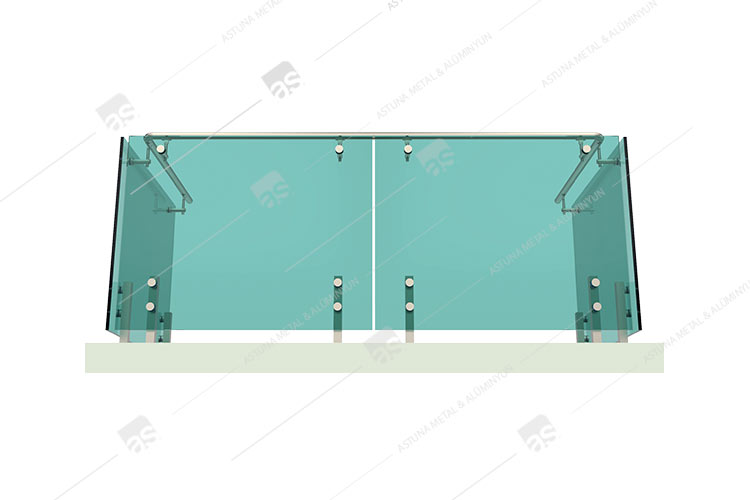

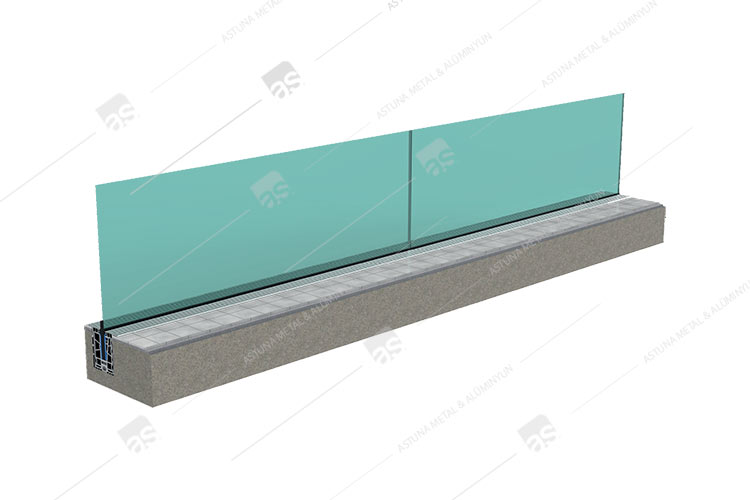

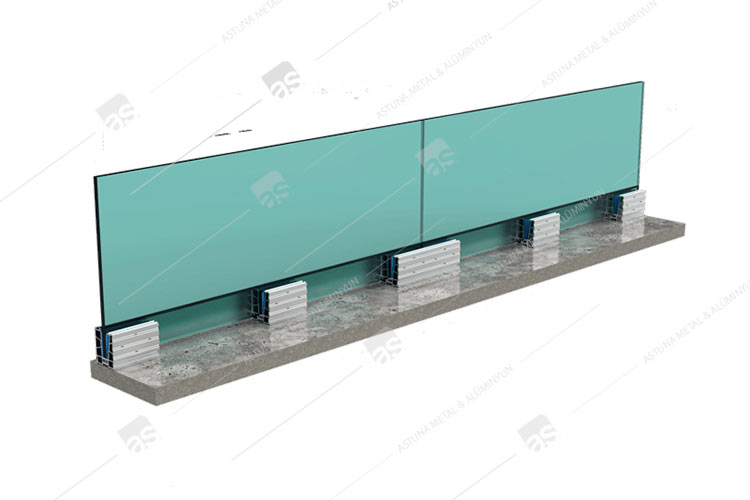

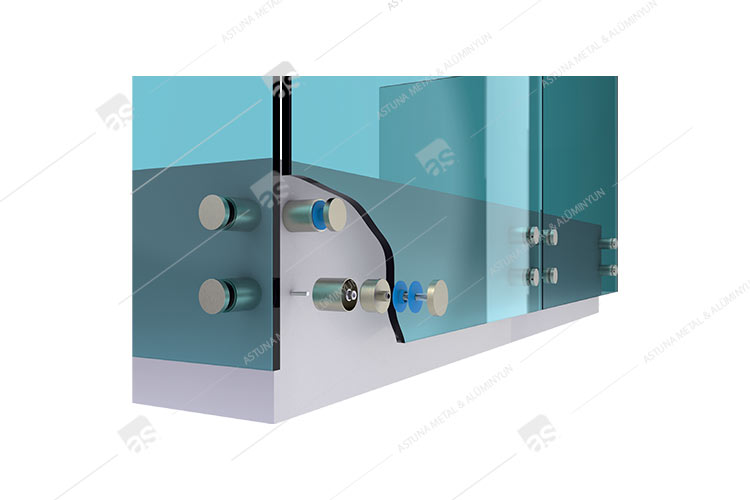

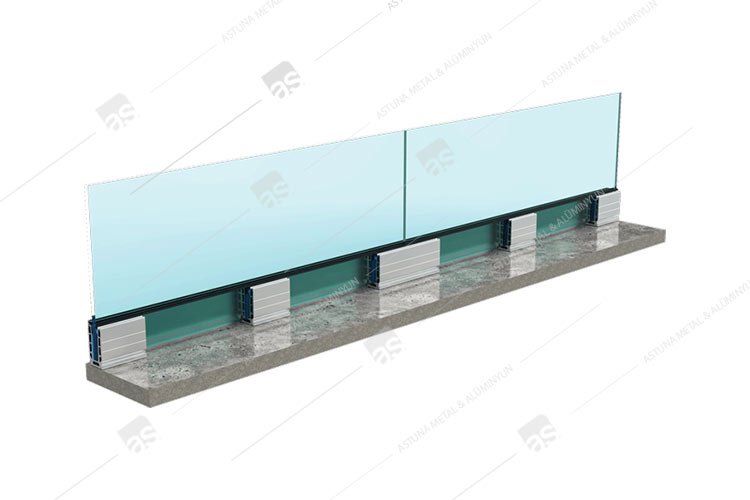

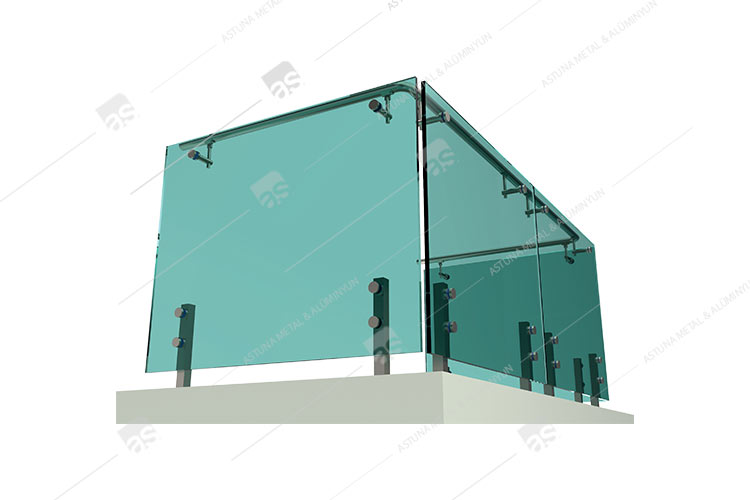

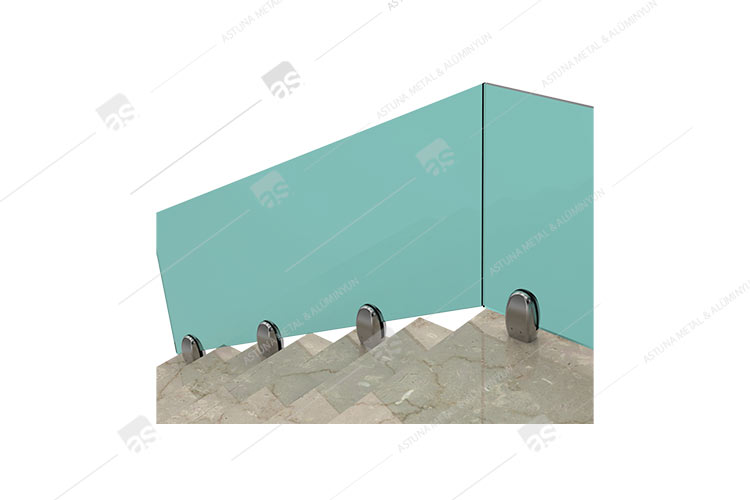

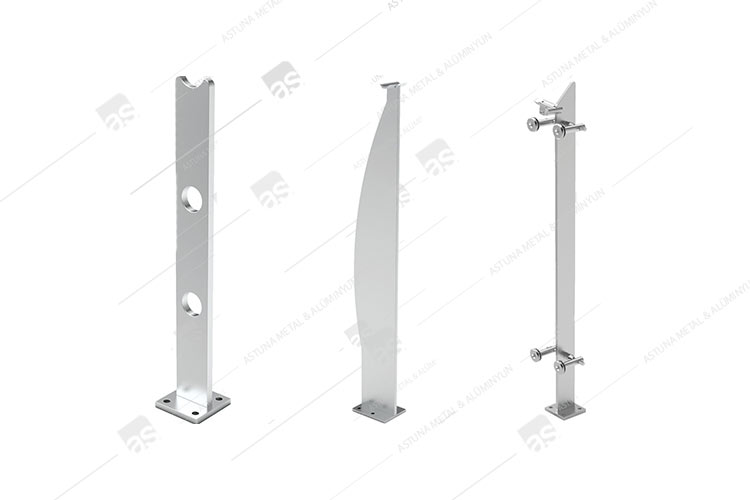

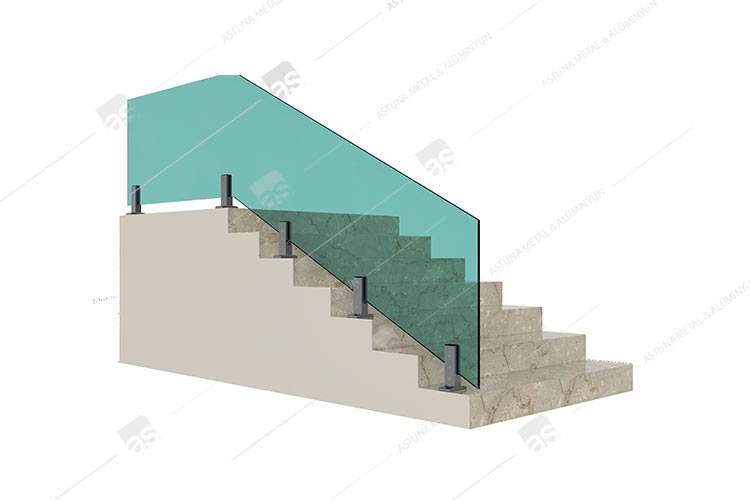

E42 GLASS BASE SYSTEM

B25 GLASS BASE SYSTEM

M84 GLASS BASE SYSTEM

AS87 GLASS BASE SYSTEM

AK61 GLASS ADAPTER SYSTEM

AS20 GLASS BASE SYSTEM

CF33 GLASS CARRIER SYSTEM

D11 GLASS BASE SYSTEM

DK10 GLASS CARRIER SYSTEM

K21 GLASS CARRIER SYSTEM

LAMA STRUTS SYSTEM

LM20 GLASS CARRIER SYSTEM

KEY FEATURES OF LASER-CUT RAILINGS

Precision and Detail: Laser cutting allows for extremely precise and intricate designs on railing materials. The laser beam is controlled by a computer, enabling accurate cutting of complex patterns with fine details.

Versatility in Material: Laser cutting can be applied to a variety of materials commonly used in railings, including metal (such as steel or aluminum), wood, acrylic, and more. This versatility allows for creative designs across different materials.

Customization: Laser cutting technology enables a high level of customization. Designers can create unique and personalized patterns, shapes, or artistic elements, providing a tailored solution for specific projects or aesthetic preferences.

Efficiency: Laser cutting is a relatively efficient process, allowing for quick and precise cutting compared to traditional methods. This efficiency can contribute to faster production times and potentially lower costs.

Consistency: Laser cutting ensures consistency in the design across multiple railing components. Each piece is cut with the same precision, resulting in a uniform and cohesive appearance.

Intricate Patterns: The technology’s ability to cut intricate patterns, filigree work, or even complex geometric shapes makes laser-cut railings a popular choice for those seeking a modern and visually appealing railing design.

Laser-cut railings are often chosen for their aesthetic appeal, modern look, and the ability to add a unique touch to architectural and interior design projects. They are commonly used in residential, commercial, and industrial settings where both functionality and visual appeal are important.

HOW TO MAKE LASER CUT RAILING

Creating laser-cut railings involves a series of steps that combine design, material selection, and the use of laser cutting technology. Here is a general guide on how to make laser-cut railings:

Design Planning: Begin by creating a detailed design for the railing using computer-aided design (CAD) software. Consider the desired patterns, shapes, and details that you want to incorporate into the railing. This step is crucial for ensuring precision during the laser cutting process.

Material Selection: Choose the material for the railing based on your design and project requirements. Common materials for laser-cut railings include metals like steel or aluminum, wood, acrylic, or other suitable materials compatible with laser cutting.

Prepare Digital Files: Convert your railing design into digital files that are compatible with laser cutting machines. These files typically include vector graphics and precise measurements. Common file formats for laser cutting include DXF (Drawing Exchange Format) or AI (Adobe Illustrator).

Laser Cutting Machine Setup: Prepare the laser cutting machine by inputting the digital files and adjusting the settings according to the chosen material. Parameters such as laser power, cutting speed, and focal length must be configured for optimal results.

Test Cuts: Before proceeding with the full production, conduct test cuts on scrap pieces of the chosen material. This helps ensure that the laser settings are correct and that the desired design is achieved accurately.

Laser Cutting: Start the laser cutting process, allowing the machine to follow the digital design and cut the patterns into the material. The laser precisely follows the outlined shapes, creating intricate and detailed patterns.

Quality Check: Inspect the laser-cut pieces for quality, accuracy, and consistency. Check for any imperfections, and make adjustments to the laser cutting settings if necessary.

Assembly: Assemble the laser-cut pieces into the final railing structure. Depending on the design, this may involve welding or securely connecting the components to achieve the desired form.

Finish and Installation: Apply any necessary finishes to the laser-cut railing, such as powder coating or painting, to enhance aesthetics and protect against corrosion. Install the completed railing according to the project specifications.

It’s important to note that creating laser-cut railings requires access to a laser cutting machine and knowledge of the specific requirements for different materials. Additionally, safety precautions, such as proper ventilation and protective gear, should be observed during the laser cutting process. If you are not familiar with using laser cutting equipment, seeking assistance from professionals is recommended.